Compounds

PSC LLC offers the following types of compounds and alloys:

ENGINEERING COPOLYESTERS

COPEnhance™ A fully compounded line of polyester materials with improved thermostability, FR, UV or combination of the above properties. Certain COPEnhance™ have UL data, what significantly reduces the time and expenses necessary for full UL cable listings. COPEnhance™ line of products designed to replace and enhance currently available products such as Hytrel 5555HS.

COPEPlus™ A specialty highly concentrated line of FR, AO, and/or UV masterbatches, designed to work with polyester resins such as Hytrel, Keyflex, Arnitel, Skypel and Kopel. COPEPlus™ line of products designed to replace and enhance currently available products such as Hytrel 30HS, Hytrel 52FR, Hytrel 21UV.

COPEnhance™ and COPEPlus™ vs. Hytrel®

| Compound | Temp. Rating, 0C | DuPont Equivalent | Functionality | Advantage of PSC product | |||

| COPEnhance™ 7211 HS FR | 105-125 | Hytrel® 7246+10% Hytrel® 52FR | FR/AO | Contains antioxidant and FR package. Improved dispersion for thin wall application | |||

| COPEnhance™ 5511 HS FR | 105 | Hytrel® 5556+10% Hytrel® 52FR | FR/AO | Contains antioxidant and FR package. Improved dispersion for thin wall application | |||

| COPEnhance™ 72A11 HS UV | 105-125 | Hytrel® 8351 NL201 | AO/UV | Contains antioxidant and UVpackage. Exhibits superior LT flexibility | |||

| COPEnhance™ 4711 HS | 105 | Hytrel® G4774 | AO/UV | Great processability. | |||

| COPEnhance™ 5511 HS | 105-125 | Hytrel® 5555HS | AO | Improved Color | |||

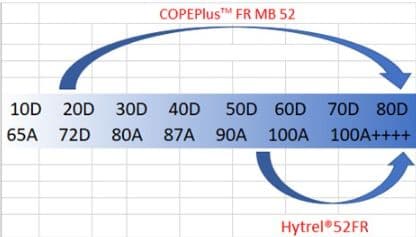

| COPEPlus™ FR MB 52 PBT | _ | Hytrel® 52FR | FR | Can be blended with wide range (30D-80D) grades COPEs vs >55D Hytrel® 52R. | |||

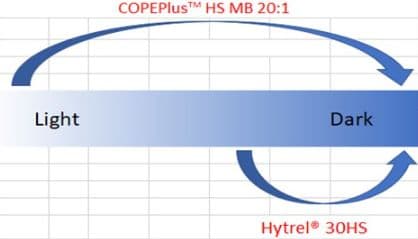

| COPEPlus™ HS MB 20:1 | _ | Hytrel® G4774 | AO | Can be blended with wide range (30D-80D) grades COPEs vs >40D Hytrel® 30HS. COPEPlus HS MB 20:1 is intended to be used in light color parts vs DuPont Hytrel® 30HS only suitable for darker applications. | |||

| COPEPlus™ UV MB 10:1 | _ | Hytrel® G4774 | UV | No minimum order | |||

| COPEPlus™ 30:1 UV MB | _ | Hytrel® G4774 | UV | No minimum order | |||

POLYOLEFINS

PSC V2-PPDIC-12 – UL 94 V-2, no/low bloom, PP based compound with unique, low halogen, low heavy metal, low/no-bloom FR package. Available as fully compounded as well as salt-and-pepper mix.

PSC PPV0 400-3-12 – Flame retardant, no-bloom, mineral filled PP based, molding grade compounds suitable for UL94 V0 rating with unique combination of good impact resistance and very high flexural modulus, comparable to GF systems.

PSC FR MB 68-37 – PP based FR concentrate, designed to be added in ratios between 15:1 to 4:1 (depending on the final FR rating requirements) directly into molding or extrusion machine with the concept to improve the economics of the final blend. PSC FR MB 68-37 is formulated to reduce the die-drool phenomena during the extrusion process.

PSCFR MB 3020/116 – TPO based concentrate, designed to make PP based roofing product suitable for French National building FR rating M1-M4 per NFP 92-510.

SUPER CONCENTRATES

PSC, in collaboration with Lumina, developed a very unique product line of flame retardant super concentrates of single additives such as DecaE (FR1410, Saytex8010); Antimony Oxide; tetrabromobisphenol A (bis)(FR720; PE68); Ethylenebistetrabromophthalimide (BT93) as well as the complete FR systems, which can be added right into the molding or extrusion machines. The new, patented technology, based on compounding concept allows the manufacturing of 90-96% active FR concentrates. As the example, 5% blend of tetrabromobisphenol A (bis) and Antimony Oxide at 2.5:1 ratio in PP gives solid UL 94 V-2 rating and 15% blend of tetrabromobisphenol A (bis) and Antimony Oxide at 2.5:1 ratio in PP gives solid UL 94 V-0 rating. This technology not only significantly reduces the cost of the final bland, eliminates dusting, but also cuts the power consumption by as much as 75%. Super concentrates can be tailored to the customer specifications.

Address

7 Whiskey Rebellion Court

Bedford NH 03110 USA

Contact Us Today!

Quick, reliable customer service

One on one personal approach

High quality TPE compounds